Non-Destructive Testing Conventional & Advanced

Non-Destructive Testing (NDT) is a varied group of test and inspection processes used to detect surface and sub-surface defects or inconsistencies in test samples, without affecting the future operating performance of the inspected parts. This category of test methods is also known as NDT Testing, Non-Destructive Examination, and Non-Destructive Evaluation.

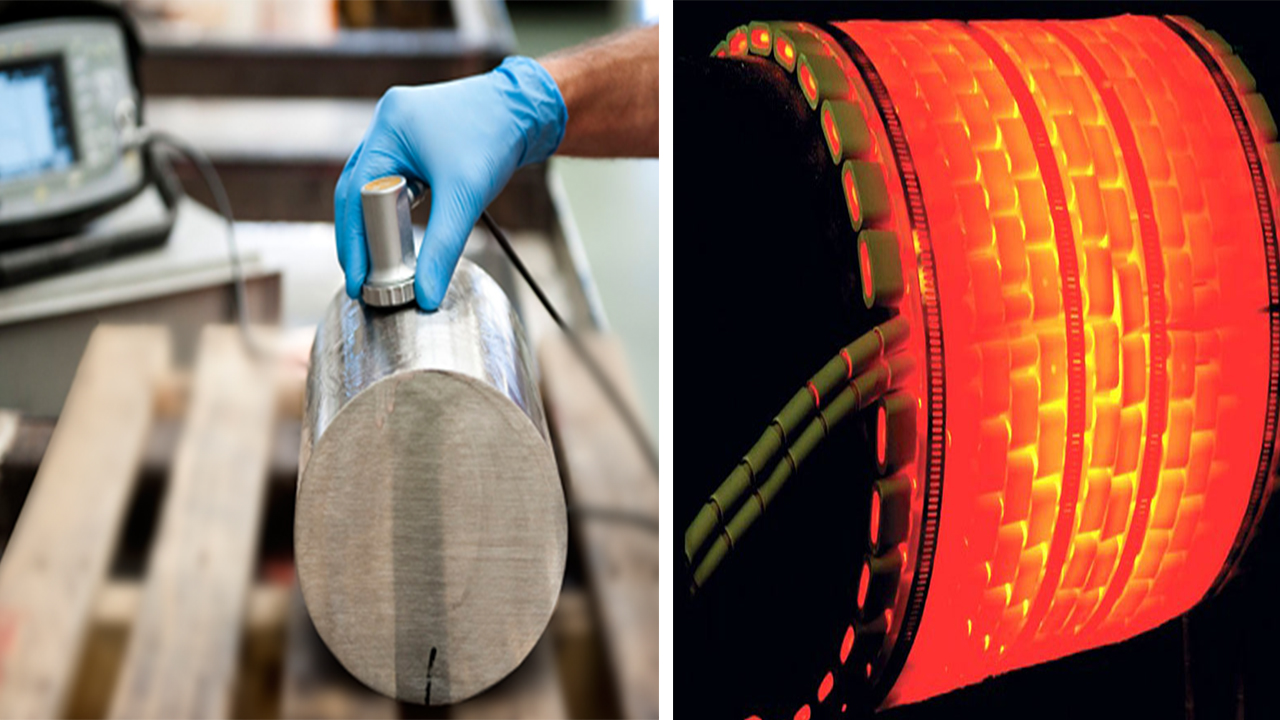

BCTS has a fully equipped testing agency that specializes in testing raw materials and finished parts made of metals and alloys. Non-destructive weld testing methods are also offered to inspect the quality of welds for Welder and Procedure Qualification and to detect corrosion.

BCTS’ non-destructive testing services help customers evaluate materials, products, and processes with proven methods that meet industry requirements and quality needs. The NDT Lab has a strict quality system and follows several procedures to ensure reliable inspection results.

Our NDT inspectors are certified to meet industry requirements, as per ASNT SNT-TC-1A & ISO.

The results of all NDT testing are evaluated by highly experienced NDT Level 2 & 3 Inspectors & Engineers.

BCTS offer the following tests and services: